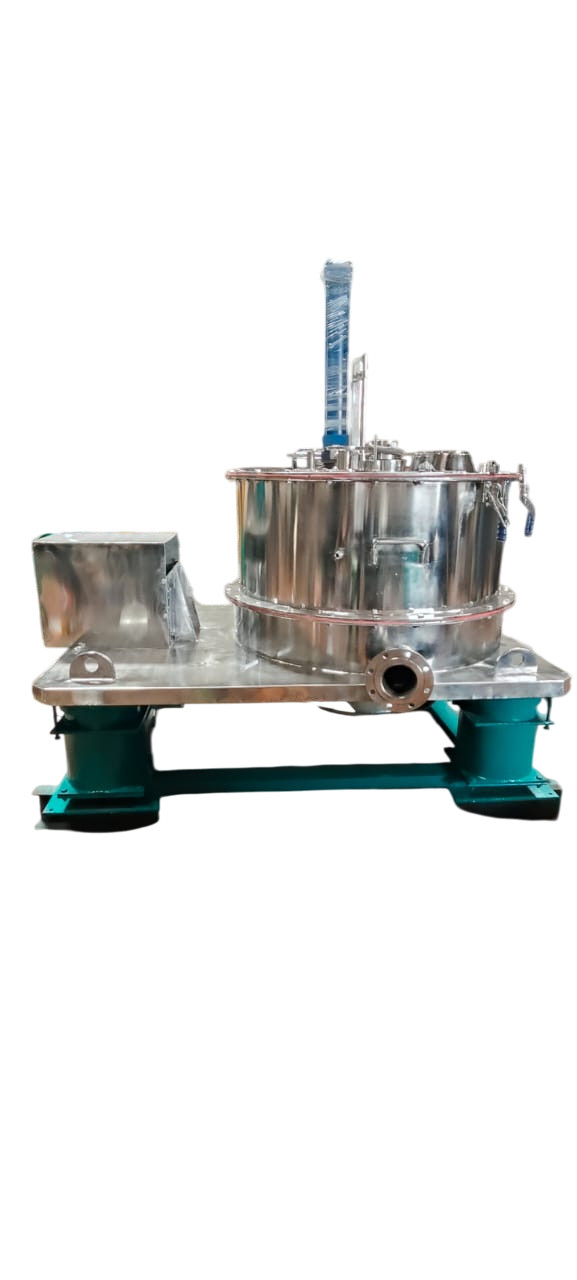

Built for heavy-duty use, the 3-Point Bottom Discharge Centrifuge offers stable performance even at high rotational speeds. The three-point suspension absorbs operational vibrations, increasing machine life and product quality. Its bottom discharge design ensures fast and complete solids removal, making it a preferred choice for high-volume production.

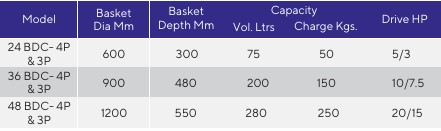

| Brand | Apollo Machinery |

| Model Type | Bottom Discharge Centrifuge |

| Category | Centrifuge Machine |

| Power Source | Electricity |

| Max Rotation Speed | 100RPM-1400RPM |

| Drive Type | 5HP-30HP |

| Capacity Volume | 70L-500L |

| Capacity Charge | 70KG-500KG |

| Construction Options | SS 304 / SS 316 / PVDF coated mild steel |

Suitable for crystalline, granular, and free-flowing solids such as APIs, fine chemicals, pigments, resins, starch, and minerals. Not recommended for sticky, compressible, or highly viscous materials that may block discharge ports.

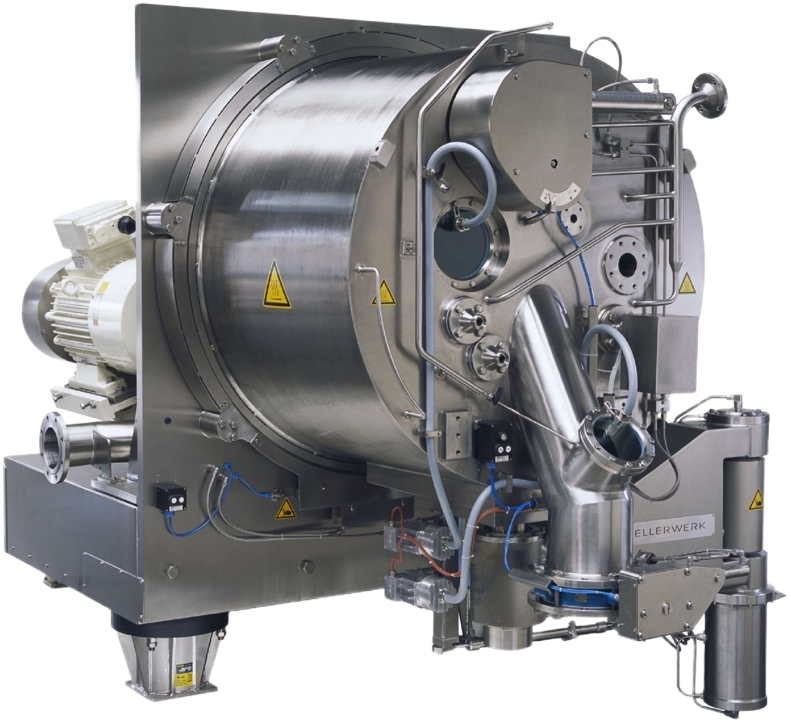

Ideal for industries requiring high-capacity, continuous separation, the Horizontal Peeler Centrifuge combines reliable performance with easy maintenance. Its horizontal design facilitates gentle handling of delicate…

A Top Driven Bottom Discharge Centrifuge is a batch-type filtering centrifuge designed for efficient solid–liquid separation. In this design, the drive assembly is mounted at…

Designed for industries that require robust performance, the 4-Point Bottom Discharge Centrifuge combines structural strength with operational efficiency. The four-point mounting provides extra stability during…