Ideal for industries requiring thorough washing and precise drying, the two-stage design allows separation processes to be customized for complex materials. The first stage focuses on coarse washing to remove bulk impurities, while the second stage provides fine washing and drying. This results in higher quality solids with reduced moisture content, all in a continuous, automated operation.

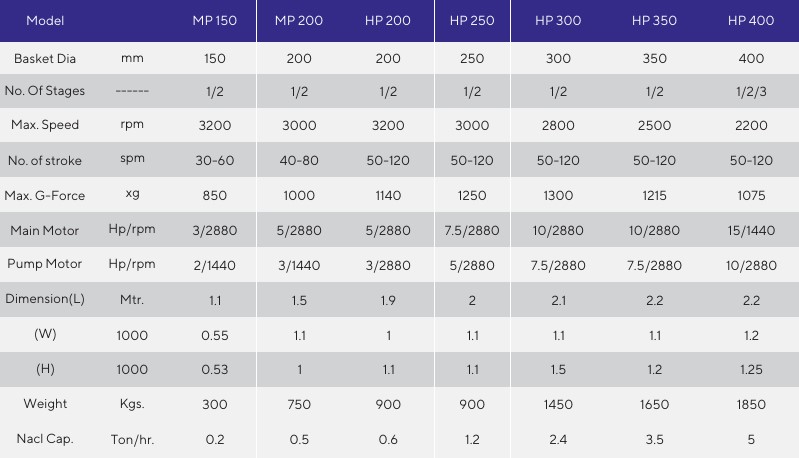

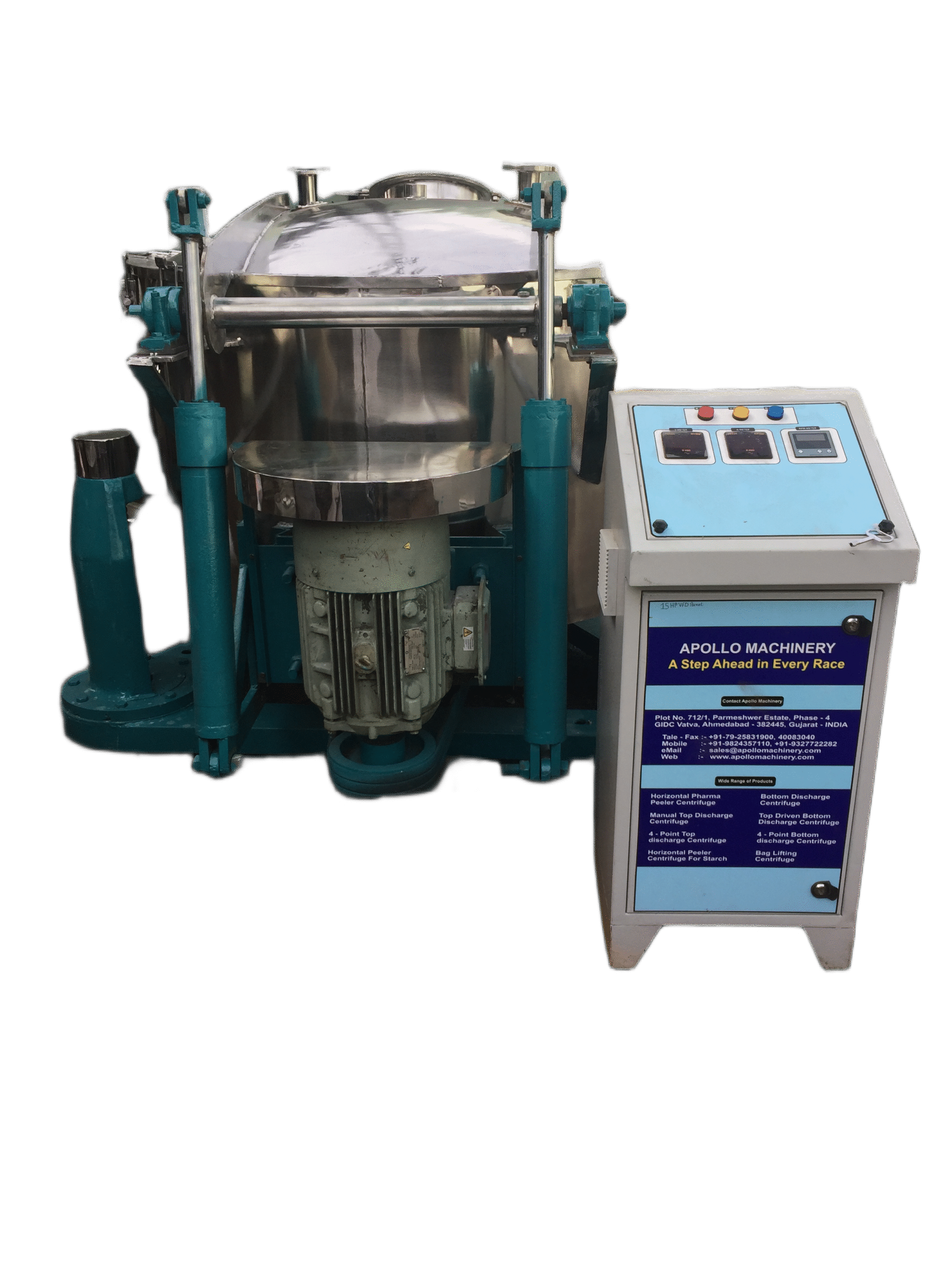

| Brand | Apollo Machinery |

| Model Type | Hydraulic Pusher Centrifuge |

| Category | Centrifuge Machine |

| Power Source | Electricity |

| Max Rotation Speed | 100RPM-280RPM |

| Drive Type | 2HP-40HP |

| Capacity Volume | - |

| Capacity Charge | 250KG-35000KG |

| Construction Options | SS 304 / SS 316 / PVDF coated mild steel |

Best suited for crystalline, granular, and fibrous solids needing intensive washing and drying, including pharmaceuticals, chemicals, minerals, and food powders. Handles sticky or moderately viscous materials better than single-stage models.

Engineered to meet Good Manufacturing Practice (GMP) standards, this centrifuge combines gentle handling of sensitive pharmaceutical solids with high separation efficiency. Its enclosed, easy-to-clean design…

The Stainless Steel Centrifuge Machine is a robust and hygienic solid-liquid separation solution designed for industries where product purity and corrosion resistance are critical. Constructed…

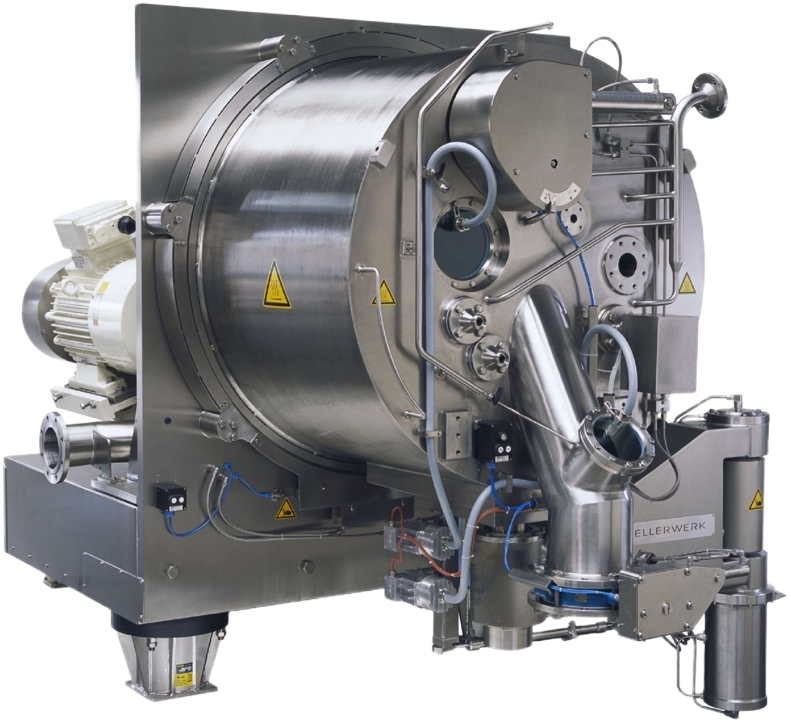

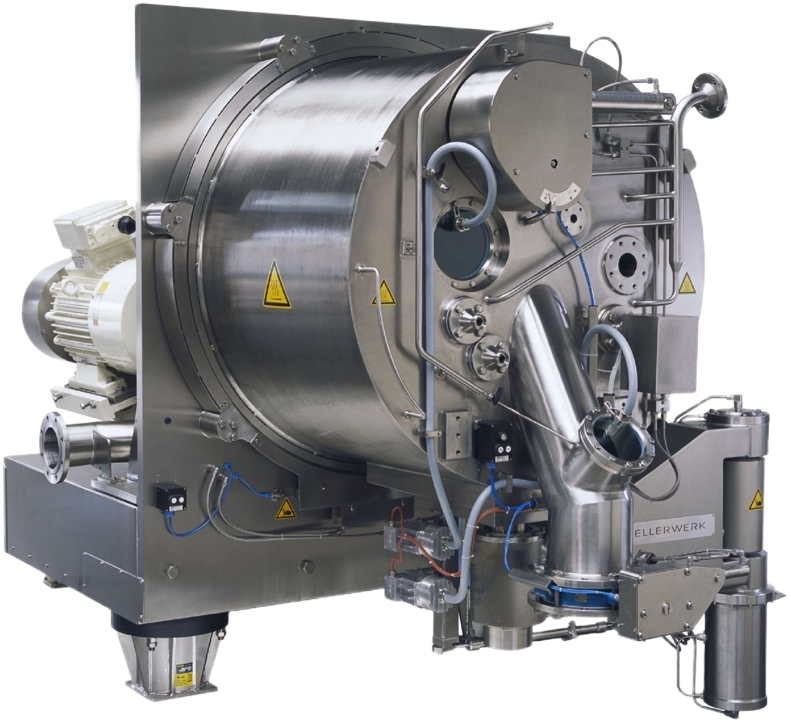

Ideal for industries requiring high-capacity, continuous separation, the Horizontal Peeler Centrifuge combines reliable performance with easy maintenance. Its horizontal design facilitates gentle handling of delicate…