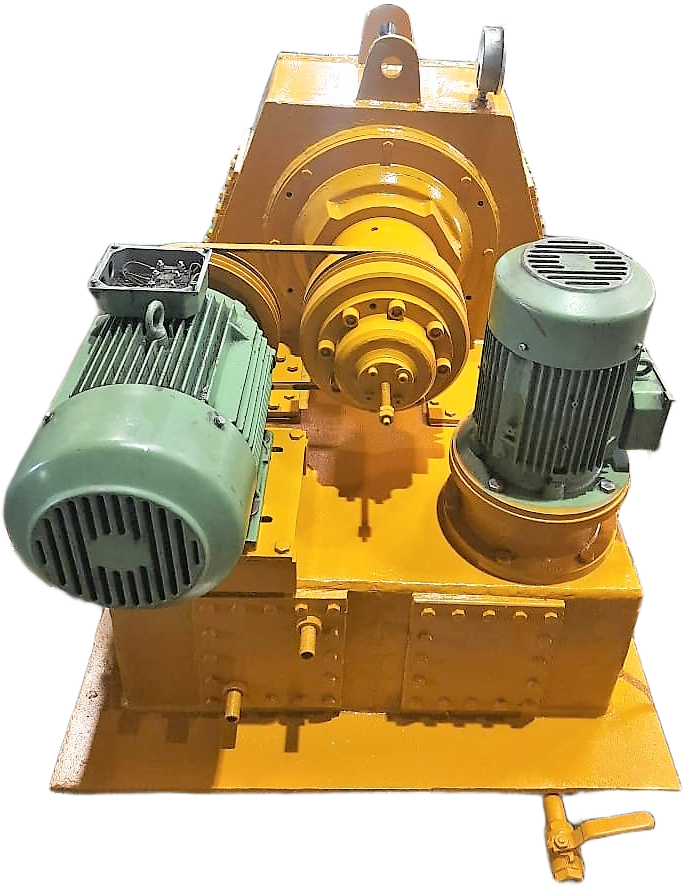

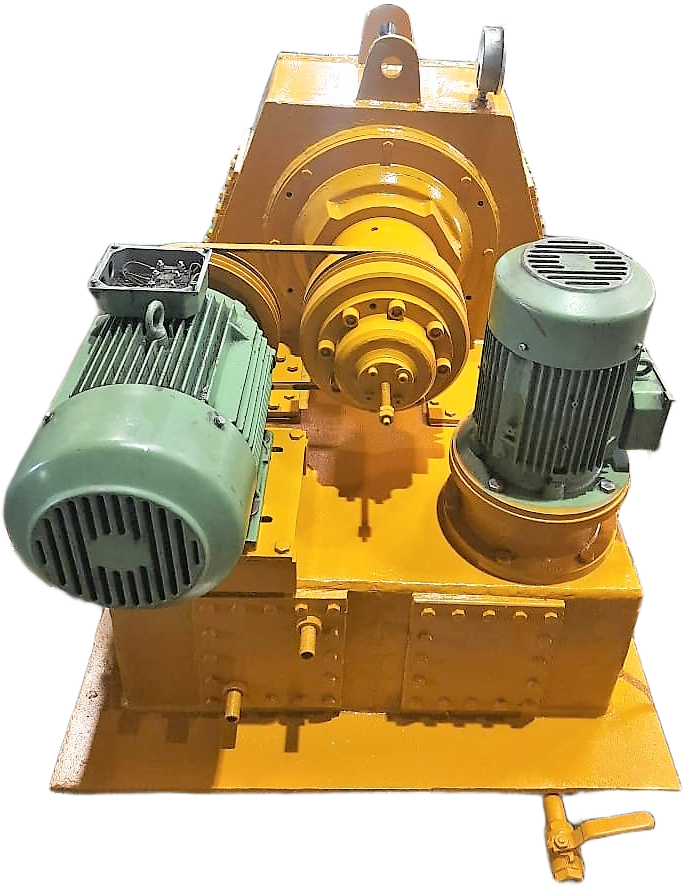

The Discharge Centrifuge is designed for efficient solid-liquid separation in a wide range of industrial processes. Built with a high-speed rotating basket and precise filtration system, it ensures maximum separation efficiency with minimal product loss. Available in durable materials such as austenitic stainless steels, PVDF-coated mild steels, and other corrosion-resistant alloys, it delivers long service life and dependable performance even under demanding operating conditions.

Engineered for easy operation, quick discharge, and minimal labor requirements, this centrifuge is suitable for applications in chemicals, pharmaceuticals, food processing, textiles, and wastewater treatment. Its robust construction, consistent output quality, and low maintenance needs make it a reliable choice for both small-scale and large-scale production environments.

| Brand | Apollo Machinery |

| Model Type | Discharge Centrifuge |

| Category | Centrifuge Machinev |

| Power Source | Electricity |

| Max Rotation Speed | 100RPN-1400RPM |

| Drive Type | 1HP-25HP |

| Capacity Volume | 10L-500L |

| Capacity Charge | 5KG-500KG |

| Construction Options | SS 316 / PVDF coated mild steel |

The Discharge Centrifuge can be manufactured in a range of high-quality materials, including austenitic stainless steels, PVDF-coated mild steels, and other corrosion-resistant alloys. This adaptability ensures safe and efficient handling of aggressive chemicals, solvents, pharmaceutical compounds, food-grade products, and abrasive slurries. Its sturdy construction and material versatility guarantee long service life, reliable performance, and safe operation in demanding industrial environments.

Built for demanding industrial environments, this centrifuge ensures continuous processing without batch interruptions. The reciprocating pusher gently transports solids through washing and drying zones, optimizing…

Designed to meet the demanding needs of the salt industry, this centrifuge handles large volumes of sea salt with minimal breakage. The pusher mechanism gently…

Built for heavy-duty use, the 3-Point Bottom Discharge Centrifuge offers stable performance even at high rotational speeds. The three-point suspension absorbs operational vibrations, increasing machine…